Sterilization wrap is a type of medical packaging material that is used to sterilize and protect medical devices and supplies. SMS, SMMS, and SMMMS represent different types of sterilization wrap materials.

SMS sterilization wrap provides a bacterial barrier that combines strength, durability, and efficiency. At the same time, the wrap is also breathable, allowing steam to penetrate during the sterilization process, but it can prevent liquids and other substances from passing through after sterilization to ensure that the contents remain sterile until they are ready to be used.

The sterilization wrap is commonly used in a variety of medical settings, including hospitals, clinics, and dental offices, to ensure that surgical instruments and other medical supplies are properly sterilized and ready for use. It is an important component of infection control and patient safety in the medical environment.

PRODUCT PARAMETERS

|

Name |

Sterilization wrap |

|

Material |

SMS, SMMS, SMMMS Nonwoven |

|

Thickness |

20 -100gsm |

|

Color |

Blue or as request |

|

Size |

As your request |

|

Packing |

1pc/sterile pack, ctn size:60x40x50cm or as request |

|

Shipping Port |

Shanghai, Ningbo |

|

OEM |

Material, Size, LOGO, Package or other specifications |

|

Quality Certification |

CE, ISO13485, EN13795 |

|

Sterile |

EO Sterile |

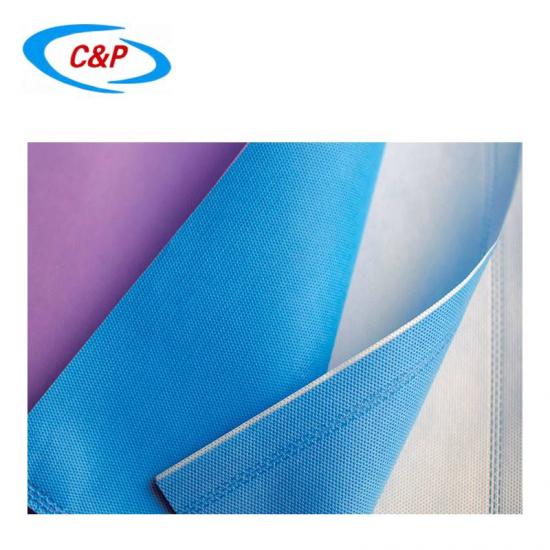

PRODUCT DISPLAY

FEATURES

1. Superior bacterial protection, strong and durable.

2. Fluid repellant and resistant to moisture, memory free.

3. Good puncture and tearing resistance.

4. Provide good filtration properties, tensile strength and are fluid repellent.

5. Ensure strong bacterial barrier properties with very small porous size.

6. For Steam, Ethylene Oxide and Low-Temperature sterilization.

COMPANY PROFILE

Hefei C&P Nonwoven Products Co.,Ltd. is a private company established in 2007, C&P located in Hefei city, capital of Anhui, C&P is a manufacturer and supplier of surgical drapes&packs, surgical gown, isolation gown, masks, equipment covers and other disposable medical products. We assemble packs specially for all kinds of surgeries. Our 3000 square meter 100,000 grade standard clean room (ISO8) space and more than 100 employees aiming to flexibility and cost effective efficiency.

OUR ADVANTAGES

1. Rich production experience: With 18 years of experience in the production of medical consumables, valuable knowledge and expertise have been accumulated in this field. Enable us to better understand the needs and requirements of the industry, in order to produce high-quality products.

2. Compliance with international standards: CE, ISO13485 certificate is an internationally recognized standard for quality management in the medical device industry. This certification demonstrates that our products and processes comply with strict safety and efficacy regulatory requirements, ensuring that our product is suitable for its intended use.

3. ISO 8 clean room: ISO 8 clean rooms provide a highly controlled environment with limited particulate matter in the air. This cleanliness is crucial for the production of certain medical consumables, as it can reduce the risk of product contamination and ensure sterility.

4. Good performance: Exported to more than 20 countries.

5. Design team: We have a professional design team can do OEM&ODM.

OUR CERTIFICATE

OUR EXHIBITION

RECOMMENDED PRODUCTS